SAN FRANCISCO – York Space Systems has learned a lot from operating its first production model spacecraft for two years in orbit. The biggest takeaway, however, was the need to automate satellite handling on the ground.

“In the first few months, it became clear that it would require as many as 15 different people to operate a constellation for a specific customer,” said Charles Beames, executive chairman of York Space Systems. SpaceNews. ‘So we started automating business. We went from 15 people to no people, to zero. ”

Through four phases of flight software development, York engineers upgraded S-Class satellites and ground systems to handle common anomalies. For example, if solar radiation causes an increase in voltage, the ground systems know how to correct it autonomously, Beames added.

York was established in 2012 to reduce the cost of satellite manufacturing and operations with a standard S-Class satellite. Automating satellite operations is the latest step in the business to increase costs and increase capacity, Beames said.

York tested its autonomous flight software as well as overall spacecraft performance during a year-long operational test. The satellite performs very well on orbit and shows that it can perform a variety of missions, including earth observation and satellite communications.

Through the test, York also determined that its satellite, which has a design duration of five years, is expected to work seven to eight years in orbit, Beames said.

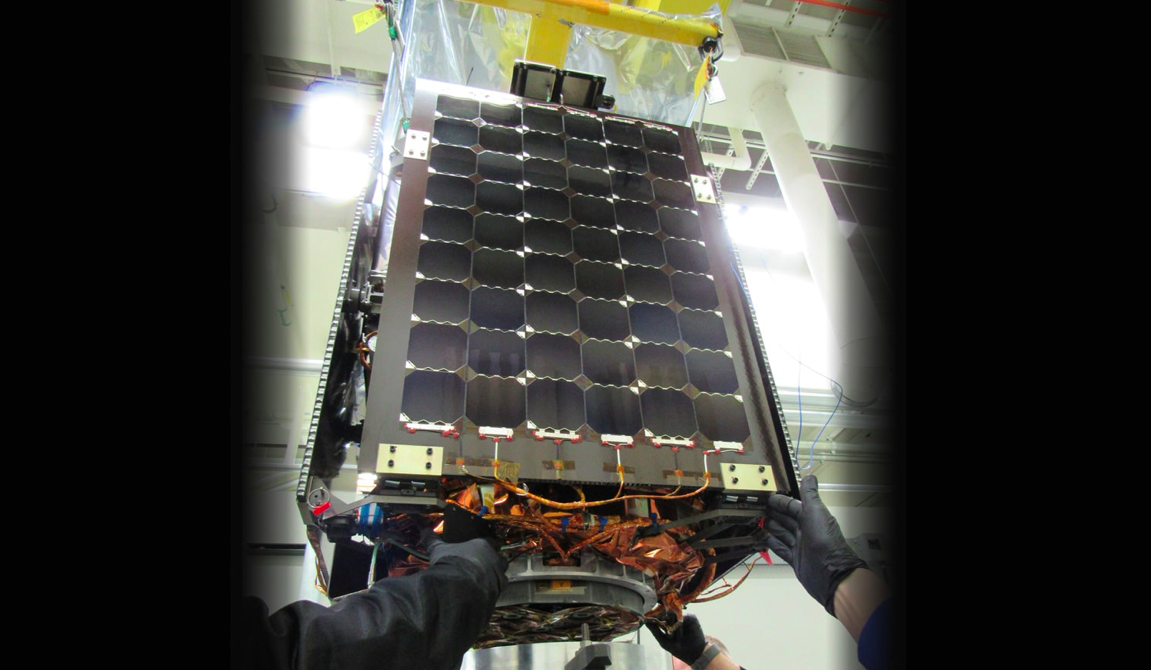

York is currently building 10 satellites at its Denver plant, designed to produce 20 spacecraft simultaneously.

“It is clear that our military now needs faster delivery than ever before, just as our commercial customers do,” York CEO York Wallinger said in a statement. “Our clients find that the ability to deliver on a track instead of four years within 90 days of the contract award is exactly what they need to outperform their competition.”