The best in-depth reporting from the Pacific and beyond is delivered to your inbox every Friday. Sign up here for the reading list.

Understanding why the $ 450 billion semiconductor industry is in crisis is a useful part of a dollar called an exhibition driver.

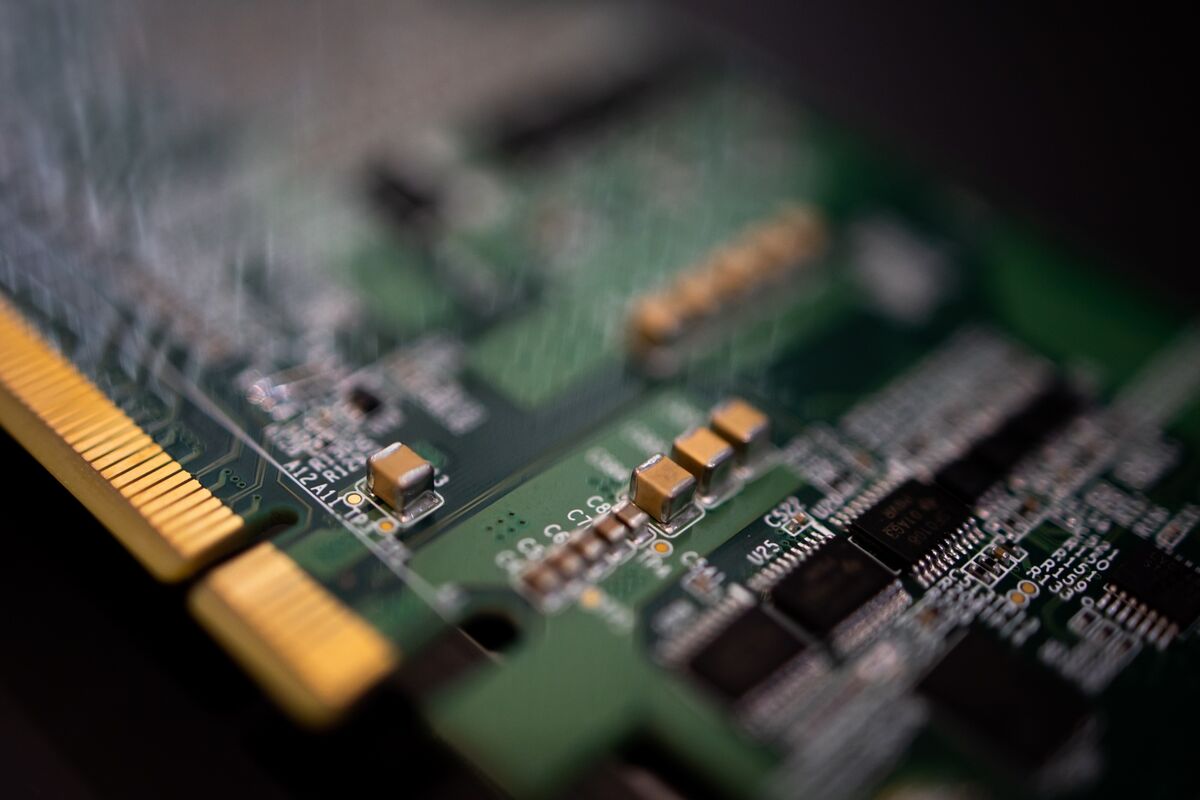

Hundreds of different types of chips form the global silicon industry, with the most flashy chips out Qualcomm Inc. and Intel Corps is going for more than $ 1,000 for $ 100 apiece. Those have powerful computers or the shiny smartphone in your pocket. In contrast, a driver slide of the display is commonplace: the sole purpose is to convey basic instructions for illuminating the screen on your phone, monitor, or navigation system.

The problem for the chip industry – and increasingly companies outside of technology, such as automakers – is that there are not enough disk drivers to go around. Businesses that make them can not keep up with the rising demand, so the prices are going up. This contributes to a shortage of supplies and increased costs for liquid crystal display panels, essential components for making televisions and laptops, as well as cars, airplanes and refrigerators.

“It’s not like you can just get by. If you still have everything but you do not have an exhibition driver, you can not build your product, ‘says Stacy Rasgon, who covers the semiconductor industry for Sanford C. Bernstein.

Now the hustle and bustle in a handful of such seemingly insignificant parts – for example, power management chips is a shortage – by the world economy. Car manufacturers love Ford Motor Co., Nissan Motor Co. and Volkswagen AG has already reduced production, leading to more than Lost revenue of $ 60 billion for the industry this year.

The situation is likely to worsen before things get better. A rare winter storm in Texas knocked out production in the US. A fire in a major factory in Japan will shut down the facility for a month. Samsung Electronics Co. warned over a “Serious imbalance” in the industry, while Taiwan Semiconductor Manufacturing Co. said he could not sustain demand despite operating factories more than 100% of capacity.

“I’ve never seen anything like it in the last twenty years since the founding of our company,” said Jordan Wu, co-founder and CEO of Himax Technologies Co., a leading provider of display managers. “Every application does not have chips.”

The chips originated from an understandable miscalculation when the coronavirus pandemic hit last year. When Covid-19 began to spread from China to the rest of the world, many companies expected people to return as times became difficult.

“I cut all my projections. I used the financial crisis as a model, ”says Rasgon. “But the question was just very resilient.”

People sitting at home started buying technology – and then kept buying. They bought better computers and bigger screens so they could work remotely. They got their kids new laptops for distance learning. They have 4K televisions, game consoles, milkshakes, air fryers and immersion mixers to make life under quarantine more palatable. The pandemic has turned into an extensive Black Friday online palooza.

Car manufacturers were blinded. They closed factories during the lock-up while demand crashed because no one could get to showrooms. They told vendors to stop shipping components, including the chips that are increasingly essential for cars.

Late last year, demand began to increase. People wanted to get out and did not want to use public transportation. Car manufacturers reopened factories and went hand in hand with disc manufacturers like TSMC and Samsung. Their reaction? Back in line. They could not make chips fast enough for their still loyal customers.

A year of poor planning has led to a huge shortage of brand new manufacturers

Himax’s Jordan Wu is in the midst of the storms of the technology industry. On a recent March morning, the brilliant 61-year-old agreed to meet at his office in Taipei to discuss the shortcomings and why it is so difficult to resolve. He was eager enough to say that the interview was the same morning that Bloomberg News requested it, with two of his staff joining in person and two more by phone. He wore a mask throughout the interview, and spoke carefully and explicitly.

Wu founded Himax in 2001 with his brother Biing-seng, now the company’s chairman. They started making driver ICs (for integrated circuits), as they are known in the industry, for notebook computers and monitors. They saw the light of day in 2006 and grew with the computer industry and expanded into smartphones, tablets and touch screens. Their chips are now used in numerous products, from phones and televisions to cars.

Wu explained that he could not make more exhibitors by pushing his workforce harder. Himax designs disk drivers and then has them manufactured at a foundry such as TSMC or United Microelectronics Corp. Its chips are made on the artificial “mature node” technology, which is at least a few generations of equipment behind the latest processes. These machines etch lines in silicon with a width of 16 nanometers or more, compared to 5 nanometers for high-end chips.

The bottleneck is that these mature slide lines become empty. Wu says the pandemic has driven such a huge demand that manufacturing partners can not make enough display drivers for all the panels placed in computers, televisions and game consoles – plus all the new products in which companies place screens, such as refrigerators, smart thermometers. and car entertainment systems.

There is a particular pressure on driver ICs for motor systems, as they are usually made on 8-inch silicone wafers, rather than on more advanced 12-inch wafers. Sumco Corp., one of the leading wafer manufacturers, reported that the production capacity for 8-inch equipment lines in 2020 was approximately 5,000 wafers per month – less than in 2017.

No one is building more adult production lines because it does not make economic sense. The existing lines are fully depreciated and fine-tuned for near-perfect returns, meaning basic screen drivers can be made for less than a dollar and more advanced versions for not much more. Buying new equipment and starting lower returns will mean much higher expenses.

“Building new capacity is too expensive,” says Wu. Friends like Novatek Microelectronics Corp., also in Taiwan, has the same restrictions.

The shortfall is reflected in a rise in LCD prices. A 50-inch LCD panel for televisions doubled in price between January 2020 and March. According to Bloomberg Intelligence’s Matthew Kanterman, LCD prices will continue to rise at least until the third quarter. There is a “serious shortage” of chips for exhibition managers, he said.

LCD prices rise

Liquid crystal prices rose during the pandemic

Bloomberg Intelligence, IDC

The weakening of the situation is a lack of glass. Major glassmakers have reported accidents at their production sites, including an eclipse at a Nippon Electric Glass Co. ‘s factory in December and an explosion in AGC Fine Techno Korea’s factory in January. Production is likely to remain limited at least during the summer of this year, DSCC co-founder Yoshio Tamura revealed.

On April 1 IO Data Device Inc., a major Japanese manufacturer of computer peripherals, has increased the price of their 26 LCD monitors by an average of 5,000 yen, the largest increase since they began selling the monitors two decades ago. A spokesman said the company could not make a profit without the increases due to the rising cost for components.

It was all a blessing in disguise. Himax’s sales are rising and the share price has tripled since November. Novatek’s shares rose 6.1% on Tuesday to a record high, pushing the year-on-year rise to more than 60%.

But Wu does not celebrate. His entire business is focused on giving customers what they want, which is why his inability to meet their requests at such a critical time is frustrating. He does not expect the predicament, especially for auto parts, to end any time soon.

“We have not yet reached a position where we can see the light at the end of the tunnel,” Wu said.

(Updates with shares in the third to last paragraph)