Scientists from the Institute of Industrial Science, part of the University of Tokyo, have devised a new technique for synthesizing concrete without cement.

Image Credit: Institute of Industrial Science, University of Tokyo.

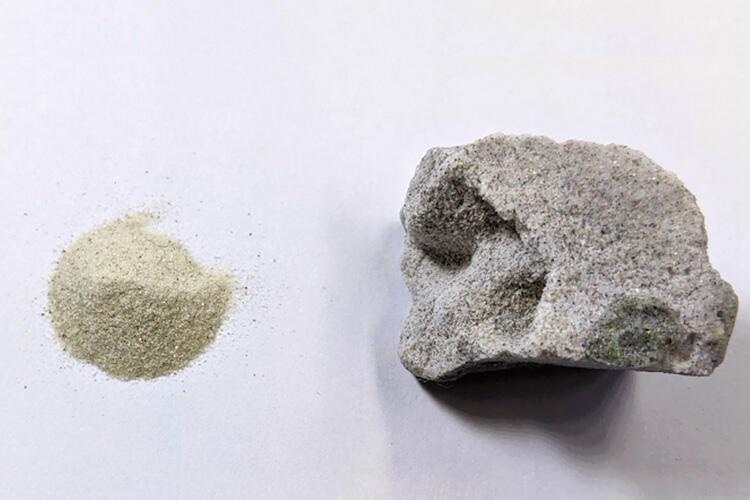

By a simple reaction in alcohol using a catalyst, the researchers bound sand particles directly. It can not only reduce carbon emissions, but also build buildings and structures in desert areas, and even on Mars or the Moon.

Concrete consists of two parts: cement (responsible for 8% of the total global CO2 emissions) and aggregate (essentially made of gravel and sand).

Despite the abundance of sand all over the world, the availability of sand for the production of concrete is quite limited, as sand particles must have a specific size distribution to make concrete flow.

In concrete, cement is used to bind sand and gravel. Some researchers are investigating how more cement can be replaced with other materials, such as fly ash and high impact, to reduce CO.2 emissions, but this approach is unsustainable because the supply of these materials decreases due to the reduced use of thermal power systems and the increased use of steel in the furnace.

Yuya Sakai, Supervisor and Associate Professor, Institute of Industrial Science, University of Tokyo

Consequently, a new method is needed to synthesize concrete from inexhaustible materials with less impact on the environment.

Sakai added, “Researchers can produce tetraalkoxysilane from sand by removing a reaction with alcohol and a catalyst by removing water, which is a by-product of the reaction. Our idea was to leave the water to shift the reaction back and forth from sand to tetraalkoxysilane, to bind the sand particles together.. ”

A cup of copper foil was placed in a reaction vessel with materials and sand, and the reaction conditions – such as the amounts of alcohol, sand, dehydrating agent and catalyst; the reaction time; and the heating temperature – has been systematically changed.

Determining the correct amount of chemicals and sand was crucial for achieving a product with sufficient strength.

We have obtained sufficiently strong products with, for example, silica sand, glass beads, desert sand and simulated moon sand. These findings could foster a shift to a greener and more economical construction industry across the globe. Our technique does not require specific sand particles used in conventional construction. It will also help address the issues of climate change and space development.

Ahmad Farahani, study second author, Institute of Industrial Science, University of Tokyo

The product probably has a better durability compared to traditional concrete, as cement paste, which is relatively weak against chemical attacks, and shows large volume changes due to humidity and temperature, is not part of the product.

The study is planned in Seisan Kenkyu, Vol. 75, 2021, as a paper entitled, “Production of hardened body by direct bonding of sand particles.”

Source: https://www.iis.u-tokyo.ac.jp/en/