For nearly seven years, they researched 3D printing systems in MIT’s Media Lab, Jifei Old SM ’14, PhD ’19, the suspicion that the work could lead to better products. He would never have thought that it would help to address supply shortages caused by a global pandemic.

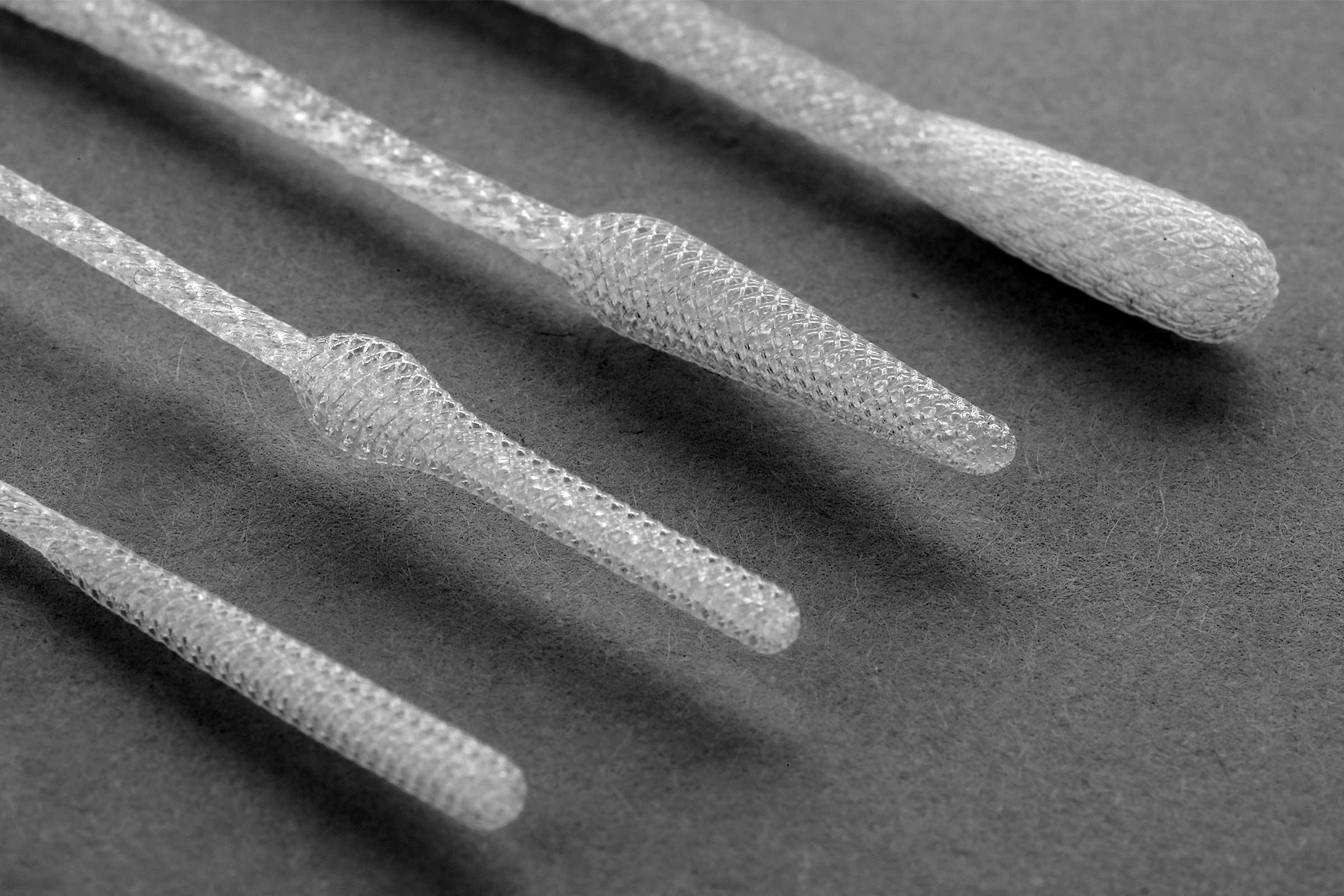

Since March last year, Ou’s company, OPT Industries, has been working with hospitals to supply a new type of nasal swab for Covid-19 testing. The swabs use thin, hair-like structures they developed during MIT. Small, woven gratings inside the OPT swabs allow them to absorb and release more fluid than regular swabs.

The MIT outlet uses a continuous manufacturing approach that makes it possible to increase printer production with demand. To date, it has provided more than 800,000 swabs to a number of health care and home testing organizations, helping to counter the shortage that threatens the hospital’s testing capacity.

In the twelve months since Old realized that OPT could play a role in the pandemic response, the small team of the company multiplied its manufacturing and distribution capability, collaborated with major healthcare organizations such as Kaiser Permanente and began developing other products that benefit can pull out of the business. design process.

“It’s very significant to be part of this effort,” says Ou. “It also feels particularly good because we’ve been developing materials with hair-like structures for a long time, so it’s like, ‘Aha, our expertise is finally being used!’ ‘

An innovation leaves the laboratory

Guy’s time as a research assistant in the Media Labs Tangible Media Group culminated in a PhD for which he created new ways to design intricate microstructures and print 3D. The work required his team to build its own 3D printer, create design software, and develop specialty polymers to meet the requirements for high durability and resolution.

Old received support from MIT Sandbox and the E14 Fund, an investment firm focused on Media Lab. Guy also acknowledges MIT’s industrial liaison program to help him secure operational connections. Guy’s team, since leaving MIT, has improved the throughput of the machines, enabling continuous printing, which has led the company to focus on creating flexible, textile-like materials.

In March last year, when hospitals across the country began running out of nasal swabs for Covid-19, Ramy Arnaout ’97, a director at Beth Israel’s clinical microbiology laboratories and an associate professor at Harvard Medical School, sent an email sent to his network at MIT and thereafter to seek help.

The next day, Ou walked into Arnaout’s office in Beth Israel with a prototype nose swab that his team put together overnight. The visit was not only remarkable for the rapid turnaround, but also for the precision with which the prototype was made.

OPT’s products are designed using algorithms that try to optimize each fiber placement. The company’s swabs contain porous microstructures in their heads that are set up to trap and retain fluid, and then release the fluid quickly when it enters a test vial.

“As for the swabs, we thought, ‘Hey, that’s very good!’ ‘Tell Ou. “Swabs must be soft, flexible, the structures at the point must be very complicated. This is what we do. ”

Old worked with members of MIT’s Center for Bits and Atoms and an external microbiology lab to compare OPTs swabs with traditional, Q-tip cotton swabs. The tests showed that patches of OPT released 20 times the amount of bacteria to test. This is important because more copies increase the sensitivity of tests, especially fast tests, according to Old.

Move forward

OPT’s additive manufacturing system allows the company to manufacture hair-like microstructures in a highly automated way, enabling OPT to compete on price with traditional swab manufacturers. The company can currently produce 80,000 swabs a day in its factory, and Ou says OPT is building newer versions of its machines that can produce products even faster.

OPT has partnered with major healthcare organizations such as distributor Henry Schein to get its swabs in hospitals, health clinics and home test kits.

The company also develops other medical sampling devices that use the high bacterial collection rate to test for other diseases. In May, OPT will move to a new office in Medford, Massachusetts, which will bring together its laboratory and production teams. Ou says the goal is to accelerate the cycle of product ideas to design, prototype, optimization and production.

‘We try to be like [the multinational products company] 3M in the manufacture of additives, ”says Ou. “Everyone knows 3M because they have many different products that are essential for daily life. This is the model we are going for. We have other medical and cosmetic products being developed – the swab is just the beginning. ”